Sheet Metal Cutting and Folding in Coimbatore

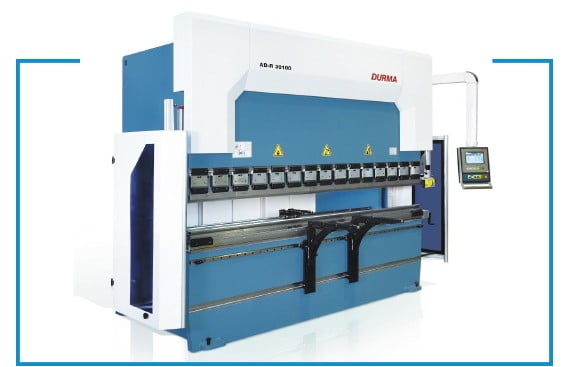

CNC BENDING MACHINE – 6 NOS

Bending and Folding

CNC PRESS BRAKE

1. DURMA – 3770 * 220 Ton

2. Hindustan Hydraulics – 3100 * 110 Ton

3. Hindustan Hydraulics – 3100 * 100 Ton

FOLDING MACHINE –Swing Beam Type Folding Machine

4. HYDROFOLD – 3125 * 5 MM

5. HYDROFOLD – 2500 * 3 MM

6. HYDROFOLD – 2500 * 2 MM

POPULAR SEARCHES

Bending and Folding services in Coimbatore

Bending and Folding service in Tamil Nadu

Bending and Folding service in Kerala

Bending Service in Tamil Nadu

Bending Service in Kerala

Bending Service in Coimbatore

Folding service in Tamil Nadu

Sheet Metal Cutting and Folding in Coimbatore

Folding service in Coimbatore

Bending and Folding in Tamil Nadu

Bending and Folding in Kerala

Bending and Folding in Coimbatore

OUR SERVICES

Sheet Metal Cutting and Folding in Coimbatore

is made up of a machine which utilized for a number of bends and may be corrected with minimal work. A simple system supports the fast and effortless exchange of resources. Its modular structure provides an inexpensive entry in the bending technologies because following an initial investment that the machine may be customized and extended later with no conversion.

That means the fundamental machine provides a bending stroke, and also the instrument determines the sort of bending machine. CNC bending machines have been designed for installation times and high flexibility. These machines have the ability to flex single bits in addition to small batches with the exact same precision and efficacy as series-produced components in a cheap manner. CNC Bending Machines in Coimbatore can be really a Fabrication procedure that generates a V-shape, U-shape, or station contour combined with a right strand in ductile substances, most often sheet-metal.

Normally used gear includes container and pan wheels, brake presses, and also other technical device presses. The beam climbs and folds sheet round a flex account. Even the Bending technological innovation spot addresses all modes of devices and procedures including Bending sheet-metal, notably media wheels, connections, and panel benders A Folding device is based onto the swinging ray which folds that the workpiece, that will be placed and held with clamping ray gear.

Bending Folding metals is a forming process. In which there is no separation of material by performing a plastic deformation to give shape around a certain angle to a sheet. It is a forming or pre-forming operation within the forming processes carried out in the machining of parts.

In panel bending, the sheet is positioned below blank-holder tools, which descend and clamp the workpiece in place, with material protruding on the other side; the machine’s bending blades from above and below move to fold the metal. Other technologies covered in this area include corner formers, ironworkers, notchers, orbital formers, and roll benders. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve a plastic deformation. Only then can you get a lasting result in the form of a bend.

Sheet Metal Cutting and Folding in Coimbatore

Sheet Metal Cutting and Folding in Coimbatore,

The bending technology area covers all manner of machines and processes for bending sheet metal, especially press brakes, folders, and panel benders. Press brakes are the most common bending equipment in fabricating shops. In a press brake, sheet metal is held in place by clamps between a matching punch and die, and the machine’s ram, with punch attached, moves down to form a predetermined bend. A folding machine relies on a swinging beam that folds the workpiece, which is positioned and held by clamping beam tools.