Screw conveyors

Conveyor Suppliers and manufacturers in Coimbatore

GK Industries, based in Coimbatore, stands as a leading conveyor suppliers and manufacturers in Coimbatore. With a strong commitment to quality, innovation, and customer satisfaction, we have earned a reputation for delivering top-notch conveyor systems tailored to meet the unique needs of our clients across various industries. A screw conveyor, often referred to as an auger conveyor, is a versatile material-handling device used for efficiently moving granular or powdery materials.

Types of Screw Conveyors

- Horizontal screw conveyors

- Inclined screw conveyors

- Shaftless screw conveyors

- Vertical screw conveyors

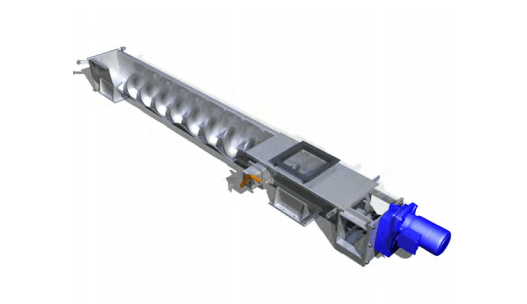

Horizontal Screw Conveyors

Horizontal screw conveyors are the most widely used type of screw conveyor. Used to convey bulk materials from one part of a process to another, conveyor manufacturers in Coimbatore offer a wide range of sizes, lengths, configurations, and materials of construction. Screw conveyors are typically designed to convey bulk materials at 15, 30 or 45-percent trough loading, depending upon material characteristics of the specific bulk material. As a general rule, trough loading of 45-percent can be used for light, free-flowing and non-abrasive bulk materials. Trough loadings of 15 and 30-percent are typically used for denser, sluggish and more abrasive bulk materials. The inlet of a screw conveyor is always control fed by another device such as Screw Conveyor, Screw Feeder, Belt Conveyor, Rotary Airlock, Volumetric or Gravimetric Feeder.

Inclined Screw Conveyors

Inclined screw conveyors typically operate from slightly above the horizontal position to 45 degrees from the horizontal position. Above 45 degrees, an inclined screw conveyor is considered a vertical screw conveyor. Conveyor manufacturers in Tamilnadu offer a wide range of sizes, lengths, configurations, and materials of construction. As the degree of incline increases, conveying efficiency is reduced and horsepower requirements increase due to the effects of gravity and bulk material fall back. Conveying efficiency is affected by angle of incline, characteristics of the specific bulk material, type of screw conveyor trough and screw pitch. Gkindus recommends designing screw conveyors using the lowest possible degree of incline for maximum efficiency.

POPULAR SEARCHES

Manufacturer of Screw Conveyors available in Coimbatore

Manufacturer of Screw Conveyors available in Kerala

Manufacturer of Screw Conveyors available in Tamil Nadu

Screw Conveyors designs and manufacturer in Coimbatore

Screw Conveyors designs and manufacturer in Kerala

Screw Conveyors designs and manufacturer in Tamil Nadu

Screw Conveyors suppliers in Coimbatore

Screw Conveyors suppliers in Kerala

Screw Conveyors suppliers in Tamil Nadu

Screw Conveyors suppliers and manufacturers in Coimbatore

Screw Conveyors suppliers and manufacturers in Kerala

Screw Conveyors suppliers and manufacturers in Tamil Nadu

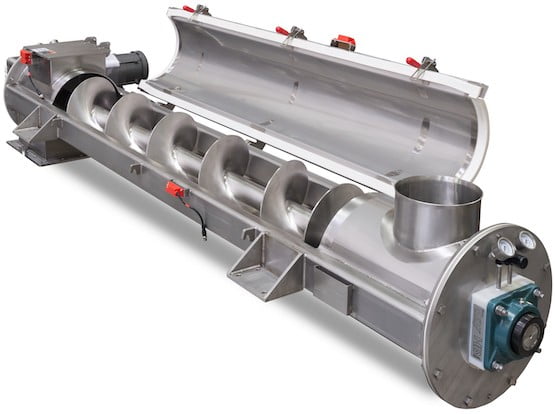

Shaftless Screw Conveyors

Bulk materials discharged from centrifuges, filter presses or mixers can easily be conveyed using a Shaftless Screw Conveyor. Our shaftless design provides a non-clogging conveying surface that allows difficult-to-convey materials to become easy-to-convey. The perfect solution for handling bulk materials with high moisture content is the Shaftless Screw Conveyor.

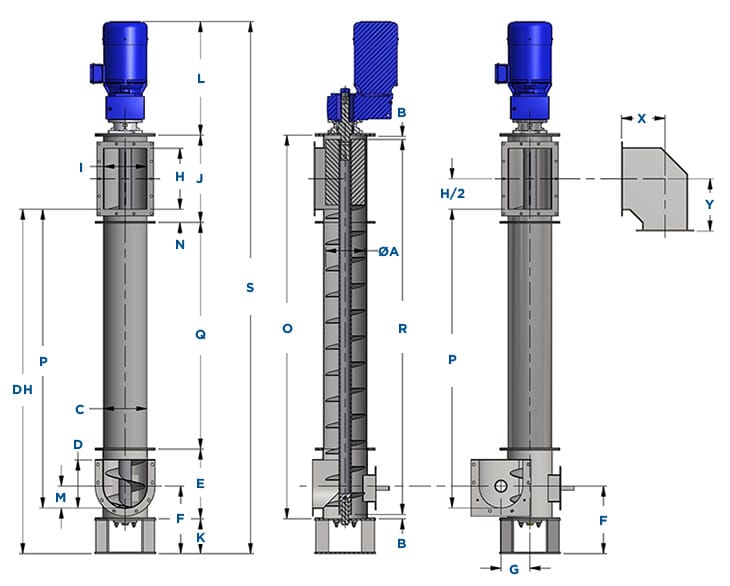

Vertical Screw Conveyors

Vertical screw conveyors are a highly efficient method for elevating a variety of raw materials at very steep inclines or completely vertical angles. Any screw conveyor located on an incline over 45 degrees is considered a vertical screw conveyor. The compact screw conveyors design allows the vertical conveyors to fit into almost any plant layout. With a minimum number of moving parts, the vertical screw conveyor is a cost-effective and dependable component of any raw material handling process.