Metal Fabrication and Job Works in Coimbatore

Partner with us for exceptional metal fabrication services that are tailored to your specific demands.

What do we do in Metal fabrication in Coimbatore?

We Provide precise quality, flexibility, on-time delivery, and competitive pricing on all products and services

CNC Laser Cutting

Excellent cutting quality repeatability precise component using Mitsubishi japan cnc laser cutting machine…

CNC Bending/Folding

Accurate folding with good repeatability multi-access 4 Meter CNC Press brake and swing beam versatile..

CNC Plasma cutting

High defined heavy plate profile cutting with economical pricing, cutting through electrically conductive ..

CNC Waterjet Cutting

Any material, any profile cold process cutting with 3D FLOW (USA)-5 Axis Waterjet Cutting Machine…

Rolling

2500mm long NC controlled heavy-duty plate rolling machine with cone bending attachments…

Pressing

250 Ton heavy-duty hydraulic press specialized for sheet metal corrugation…

NC Shearing

4 Meter Servo controlled precise shearing.NC controller for backgauge control, manual adjustment ..

CNC Turret Punching

Amada (JAPAN) CNC 30 Station turret punching machine with high quantity punches…

Fabrications

Ending products defined with engineering quality, It is a value-added process involving the creation …

OUR RECENT METAL FABRICATION PROJECTS IN COIMBATORE

We are Proud to Present our Range of Products

Architectural Designs

Steel, Tiles, Rubber, Marble, Acrylic, Granites, Glass MDF, Plastics, Polystyrene, Wood, and many more.

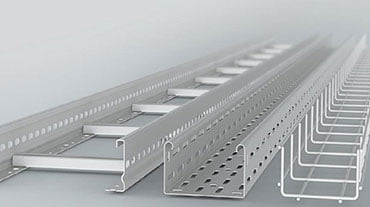

Cable Trays

We manufacture finest quality Perforated cable trays, Ladder Type Cable Trays, Solid Bottom Cable Trays

Bus Body Sections

Section for bus body frame manufacturing, gusset, and all sheet metal sections for frame

WELCOME TO GK INDUSTRIES

GK industries,

an ISO 9001:2015 certified company, boasts a rich history of 50 years in manufacturing and exporting diverse sheet metal components. Our expertise lies in crafting customized designs that cater to our customers’ specific applications.

Established in 1971, our journey began with job working for renowned textile and engineering firms. It’s a matter of great pride that we’ve consistently received accolades for delivering high-quality products on time. Welcome to GK Industries – Your Gateway to Outstanding Metal Fabrication Services. GK Industries is your go-to destination for top-tier metal fabrication services and job works in Coimbatore, Tamil Nadu. Our unwavering commitment to excellence is evident in every project we undertake.

Why Choose GK Industries for Metal Fabrication Services in Coimbatore ?

Unwavering Precision

Our dedication ensures highest standards of precision in every aspect of our work.

Tailored Solutions

We customize our services to meet your unique project requirements, ensuring a perfect fit.

Punctual Delivery

We recognize the significance of meeting deadlines, and we consistently deliver your projects as promised.

Competitive Pricing

Our competitive pricing structure guarantees exceptional value for your investment.

ARCHITECTURAL DESIGNS

Fancy Huge Architectural Designs, With Endless possibilities, What else request your needs to create your designs.

Experience The High-Quality Sheet Metal Manufacturing in Coimbatore

At GK Indus We Provide High-Quality Sheet Metal Components At Competitive Prices, Delivered On Time With A Wealth Of Experience..

Customers Satisfaction

Years of Experience

Product Development

OUR CLIENTS

Below, you will find an extract from our client list, our happy clients.