SHEARING

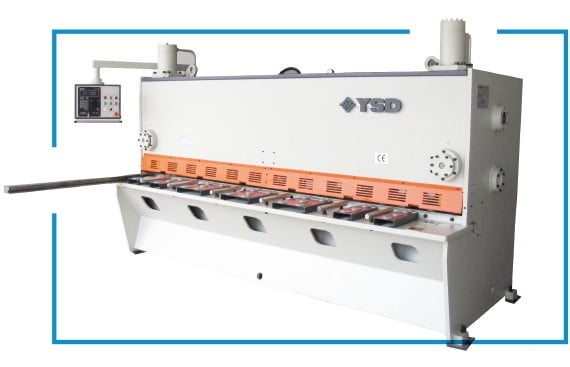

NC SHEARING MACHINE

NC SHEARING – 3 NOS

Specification

Maximum Thickness

MS : 4100 * 10 mm

SS : 4100 * 06 mm

POPULAR SEARCHES

Shearing Machine service in Coimbatore

Shearing Machine service in Kerala

Shearing Machine service in Tamil Nadu

Shearing Machine service provider in Coimbatore

Shearing Machine service provider in Tamil Nadu

Shearing Machine service provider in Kerala

Shearing Machine in Coimbatore

Shearing Machine in Kerala

Shearing Machine in Tamil Nadu

Shearing Machine in Coimbatore,

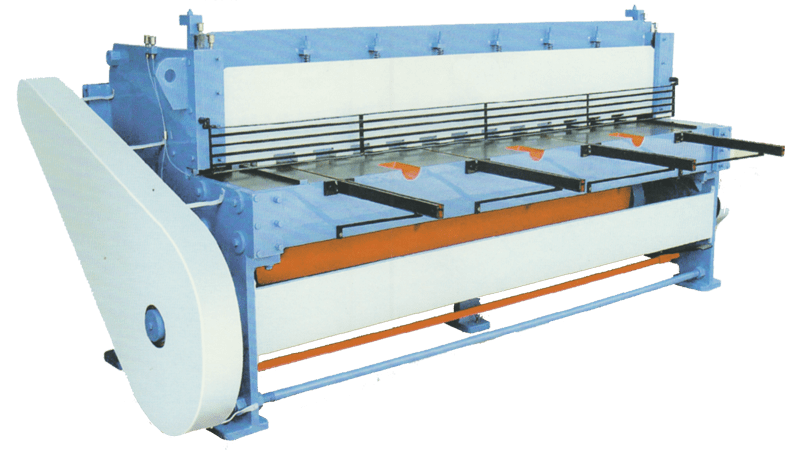

also called die cutting edge, is a procedure that cuts inventory minus the formation of the usage of melting or burning. Strictly speaking, if the cutting blades are directly the approach is called shearing; when the cutting blades are curved afterward they’re shearing-type operations. The most frequently sheared substances are in the kind of sheet metal or plates, nevertheless, rods may also be shared. It’s used in metalworking and in addition to plastics and paper. A punch (or transferring blade) can be used to push a workpiece from the expire (or fixed blade), which can be fixed. Normally the clearance between both is 5 to 40 percent of the depth of this substance but determined by the substance.

Laser cutting for metals has the advantages over plasma cutting of being more precise and using less energy when cutting sheet metal; however, most industrial lasers cannot cut through the greater metal thickness that plasma can. Newer laser machines operating at higher power (6000 watts, as contrasted with early laser cutting machines’ 1500 watt ratings) are approaching plasma machines in their ability to cut through thick materials, but the capital cost of such machines is much higher than that of plasma cutting machines capable of cutting thick materials like steel plate.

Clearance is defined as the separation between the blades, measured at the point at which the cutting action happens and vertical to the path of blade motion. It impacts the end of this cut (burr) as well as the system’s power intake. The substance will then fail if the chalk has transferred 15 to 60 percent the depth of this substance since the shear stresses are higher compared to the shear strength of this substance and the rest of the substance is ripped. Two different sections can be understood on a sheared workpiece, the first component being plastic deformation along with the moment being fractured. Other, even greater machines make use of a more direct Shearing activity with all the blades repaired at an angle rather than this rotational motion. This machine surgeries are done with the actions of 2 blades, and a single mended at the shear mattress and also another moving with Little If Any clearance in GKindus

Shearing Machine

in Coimbatore, also known as die cutting, is a process that cuts stock without the formation of chips. Clearance is defined as the separation between the blades, measured at the point where the cutting action takes place and perpendicular It affects the finish of the cut (burr) and the machine’s power consumption.

The very first rung on the ladder into creating a sheet metallic component would be clipping on dimensions. Shearing devices have been multi-purpose apparatus utilized at the cutting edge of metals along with other sheet metal. Some inkjet machines utilize a scissor-like, angular Shearing activity to decrease metal into sheets or strips. Shearing devices and machines do such specific functions.