Cleats manufacturer

What is Cable cleats…?

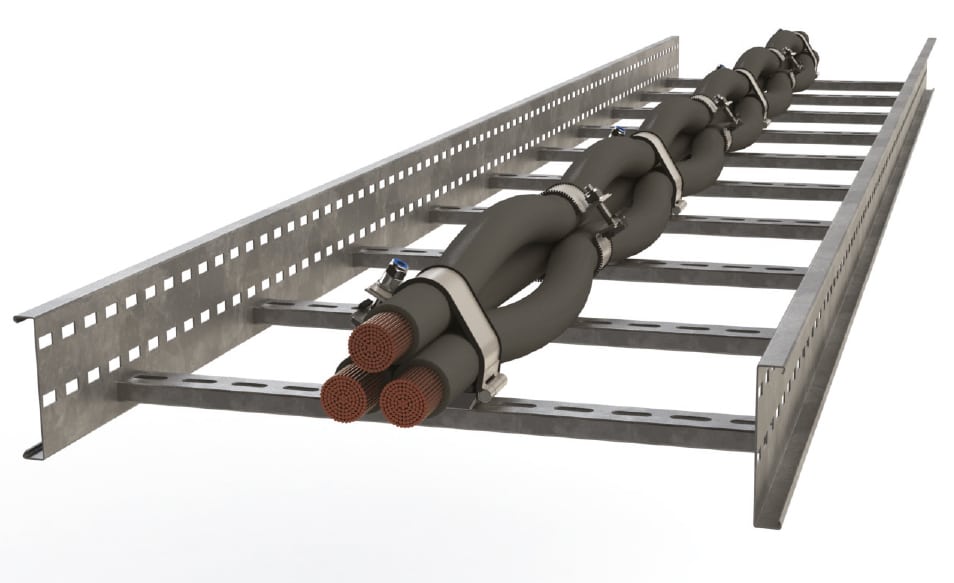

Cable cleats

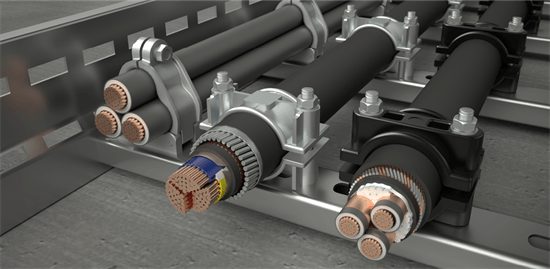

are used to fix, clamp and support cables – cleats provide effective short protection, support and retention to low voltage(LV), medium voltage(MV) and high voltage(HV) power line systems when installed at intervals to circuits to secure electrical installations. The cable cleats prevent excessive cable movement resultant from fault-current magnetic forces and supply restraint.– cleats must be suitably rated for cable size (outside diameter) and anticipated fault current (peak fault level kA). Cable cleats will withstand the forces like the values of the height prospective short-circuit current. Cable cleats are available all environmental conditions (onshore and offshore), industrial applications and operating voltages – specialist cable fixings for fire resistant, (LSF LSOH)low smoke zero halogen and (Quad)quadrafoil cable installations.

Why cable cleats…?

During a short circuit fault, maximum electromechanical stress between conductors occurs at or before 0.005 second

Typical circuit breakers and other protection devices trip and interrupt a fault between 0.06 to 0.1 second

Cable cleats perform their function within those first 0.005 second (i.e.at peak kA) before a circuit breaker trips and interrupts a fault

Reduce project cost and Installation time

- Simple and intuitive design results in increased productivity

- Compatible with a range of ladder racks and cables

- Industry-unique mounting brackets and installation tool

- Tested to IEC 61914:2015, the newest/latest and most globally recognized cable cleat testing standard

- Collaborative and consultative approach to cable cleat specification, supported by a team

- Applications: Oil and Gas, Petrochemical, Shipbuilding, Rail, Utilities and Data Centers

TREFOIL CLEAT – STAINLESS STEEL MATERIAL

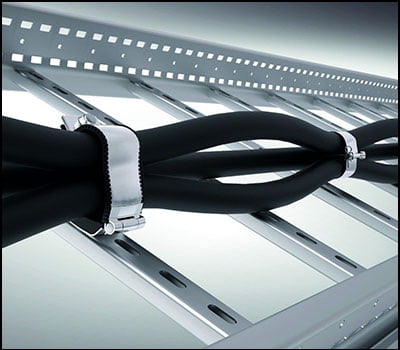

The stainless steel Buckle Strap Cleat is an efficient option for shielding against high short fault current requirements in harsh environments. The strap is formed of 316L stainless steel , has inherent cable range-taking, and is compatible with quad, trefoil, and multicore cables. The cleat is installed after running the cable via unique in the industry mounting bracket. it’s tensioned and cut employing a manually-operated, ratchet-style installation tool or a tension screw drive installation tool. The straps have rounded edges to guard from damaging the cable and are often utilized in combination with a cushion sleeve inserted between the strap and cable for added protection

LOCKING STRAP CLEAT – STAINLESS STEEL MATERIAL

The stainless steel Locking Strap Cleat is an efficient option for shielding against lower to medium short fault current requirements in harsh environments. The strap is formed of 316L chrome steel , has inherent cable range-taking, and is compatible with quad, trefoil, and multicore cables. The cleat is installed after running the cable via a singular within the industry mounting bracket. it’s tensioned and cut employing a battery-operated, electromechanical or manually-operated, ratchet-style installation tool. The straps have rounded edges to guard from damaging the cable and are often utilized in combination with a cushion sleeve inserted between the strap and cable for added protection.

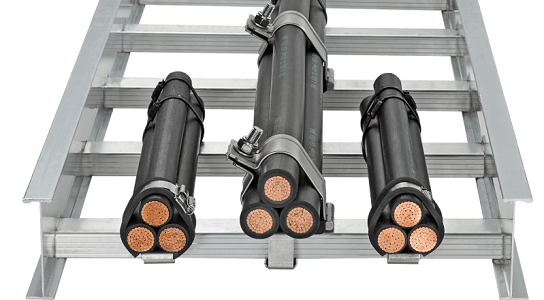

TREFOIL-CLEAT – ALUMINUM MATERIAL

ALUMINUM TREFOIL CLEAT The Aluminum Trefoil Cable Cleat is right for medium-high short faults in less corrosive environments. it’s available in multiple sizes with cable range-taking capability and is suitable for trefoil cable arrangements. The cleat are often installed after running cable via unique in the industry mounting bracket or before running cable through it by installing direct to the cable tray rung via a fixing hole and M8 bolt. Insulating spacers and washers are available to guard against galvanic corrosion between dissimilar cable tray rung and cable cleat materials.

TWO-HOLE-CLEAT – ALUMINUM MATERIAL

The Aluminum Two-Hole Cleat is right for medium-high short faults in less corrosive environments. it’s available in multiple sizes with cable range-taking capability and is suitable for single conductor cables. The cleat is installed after running cable by installing direct to the cable tray rung via fixing holes and two M10 bolts. Insulating spacers and washers are available to guard against galvanic corrosion just in case of dissimilar cable tray rung and cable cleat materials.

ONE-HOLE-CLEAT – ALUMINUM MATERIAL

The Aluminum One-Hole Cleat is right for lower to medium short faults in less corrosive environments. it’s available in multiple sizes with cable range-taking capability and is suitable for single conductor cables. The cleat is installed after running cable by installing direct to the cable tray rung via a fixing hole and M10 bolt. Insulating spacers and washers are available to guard against galvanic corrosion just in case of dissimilar cable tray rung and cable cleat materials.

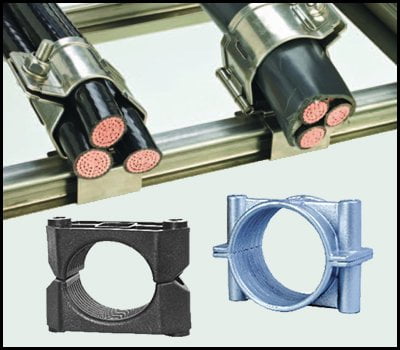

TREFOIL-CLEAT – POLYMER MATERIAL

The Polymer Trefoil Cleat is right for medium-high short faults in less harsh environments. it’s available in multiple sizes with cable range-taking capability and is suitable for trefoil cable arrangements. The cleat is installed after running cable by installing direct to the cable tray rung via a fixing hole and M10 bolt.

TWO-HOLE-CLEAT – POLYMER MATERIAL

The Polymer Two-Hole Cleat is right for lower to medium short faults in less harsh environments. it’s available in multiple sizes with cable range taking capability and is suitable for single conductor cable arrangements. The cleat is installed after running cable by installing direct to the cable tray rung via fixing holes and two M10 bolts.

ONE-HOLE-CLEAT – POLYMER MATERIAL

The Polymer One-Hole Cleat is right for lower to medium short faults in less harsh environments. it’s available in multiple sizes with cable range-taking capability and is suitable for single conductor cable arrangements. The cleat is installed after running cable by installing direct to the cable tray rung via a fixing hole and M10 bolt.

Cable Cleats Uses

High end customization on the cable cleats with a fine fusion of material and multiple functionalities are dropped at market. These sorts of cable cleats are used for efficient and secured installation of cable glands and supply protection to cables at the time of short circuit electrical system. It also makes a systematic arrangement of cables for smooth operations.

How to select cable cleats…?

The Cable Cleats and other cable fittings that are used in HV, LV and MV cables need a special design outlay which will perfectly suffice the appliance purpose. Depending on the purpose of its accessibility, few important aspects must be considered to pick out an appropriate connector cleat for cable gland installation. The load within the cable mechanism, the horizontal or vertical cable run, the climatic reactions, temperature requirement, complimenting the cable support structure and therefore the easy cohere to the cable diameter are the facet of prime consideration before the ordination of cable cleats.

GK Industries solutions for electrical and networking installations

From Breaking Ground to Routine Maintenance and Repair, Panduit Products Impact Your Entire Project Lifecycle Partner with a corporation committed to meeting the daily challenges you face. GKINDUS offers a full solution of over 30,000 readily available parts – from cable ties to power connectors, terminals to identification – GKINDUS products are engineered for all aspects of designing, installing and maintaining infrastructures within heavy-duty industrial environments.

Productivity – Reduce costs and meet deadlines with products and tools engineered to enhance efficiency

Reliability – Ensure performance and style consistency of products that are vital to the success of the workSafety – Protect personnel, equipment and infrastructure

POPULAR SEARCHES

Manufacture of Cable Cleats in Coimbatore

Manufacture of Cable Cleats in Kerala

Manufacture of Cable Cleats in Tamil Nadu

Cable Cleats supplier in Coimbatore

Cable Cleats supplier in Kerala

Cable Cleats supplier in Tamil Nadu

Manufacturer of Cable Cleats Machine in Coimbatore

Manufacturer of Cable Cleats Machine in Kerala

Manufacturer of Cable Cleats Machine in Tamil Nadu

Cable Cleats Machine required in Coimbatore

Cable Cleats Machine required in Tamil Nadu

Cable Cleats Machine required in Kerala

Cleats Manufacturer – GKINDUS

Gkindus

is the most trusted and leading manufacturer, supplier and exporter of Cable Cleats. Gkindus is specialized in Design, manufacturing and distribution of innovative cleats. we provide the most effective latest solutions to our clients with a world Technology through synergetic alliance with the specialist companies. These cleats are produced from great caliber, UV settled, phosphorus safe no halogen dark nylon polymer, possessing a Constrained Oxygen List and Combustibility Rating and additionally suiting the worldwide standard.

Cleats used to clamp and retain low, medium and high voltage cables within the event of a brief circuit, including 11kV/33kV MV-HV power cables – single, multi-core, trefoil, quadrofoil and multiple bundled cable configurations is cleated using our greatest quality manufactured cable cleats in an exceedingly choice of materials including nylon, stainless steel and aluminium. With quality being a sincere concern in the cable gland market importance is additionally noticed within the cable accessories and cable cleat manufacturing to form the cable installation a simple one with tough functionalities. With growing technological development and innovations, the necessity for safety in electrical equipment has become a sensitive concern. The increased electrical accidents and machine breakdown within the units, has now raised the issue to manage the value of asset maintenance. Be it a simple industrial requirement or safety of hazardous area, cable glands are name of the game for installing a protective cable system within the machineries/ device/tools/instrument. Cable cleater and solution with quality cable accessories has now become a priority of investment to save lots of the business from a sudden loss and misfortunes within the business operations.

Available during a various sizes, extensive line of cable cleat solutions ensures cables remain contained within the event of a brief circuit fault, minimizing disruption and damage to personnel and property. gkindus Cable Cleats are uniquely engineered for simple installation during a range of applications and harsh environments. With a spread of cable cleats, gkindus has the proper product to suit your needs while providing on the work productivity, reliability and safety.

multi cleat system is high demand altogether dominant sectors that appears out for a troublesome secured cable solution. The researchers and cable cleat manufacturers are striving to bring a fine blend of the modifications within the cable cleat varieties. a number of them are often seen with increased use of ergonomic design and rich in features with its suitability for normal ladder and tray system to engineer the cable cleats for smooth cable installation.

Our cleats are acknowledged for their attributes like easy installation, low maintenance, corrosion resistance, perfect finish and dimensional accuracy. Due to these features, our cleats are most preferred in electrical, construction and engineering industries. Our cable cleats are suitable to be used with cable diameters 30 to 135 mm for a wide range of uses like clamping rail power, S&T cables at the station, sub-surface and tunnel applications. Our high-quality Cable Cleats are well known by our worldwide customers.